Hitachi Power Solutions Co., Ltd.

Hitachi Construction Machinery Co., Ltd.

Classification

4 - B : Repair/Replacement,

5 - B : Improvement

Presently, robots are deployed in the Fukushima Daiichi Nuclear Power Plant (NPP) for the implementation of survey, measurement and so forth in a high radiation environment with the buildings by remote control. Additionally, in the future it is anticipated that there will be an increasing need for the robots to be used for the removal of rubble, installation of shielding and so forth. Furthermore, it is deemed necessary to prepare the robots for the decontamination work required to improve the environment within the buildings, and to apply the robots to the subsequent survey and repair works for reactor containment vessels.

To respond to such a need for the application of remote-controlled robots, development works have been in progress for a remote-controlled robot system utilizing wireless communication technology, a gamma camera for the measurement of gamma-ray intensity distribution, a small-scale double-arm heavy machinery-type robot for disaster-handling use “ASTACO-SoRa” and a remote-controlled decontamination device by using high-pressure water “Arounder”, thereby providing the capabilities to enable the robot to perform site surveys, rubble removal and an improvement in the environment.

This paper provides an introduction to the small-scale double-arm heavy machinery-type robot for disaster-handling use “ASTACO-SoRa” that is one of the above-mentioned robots developed thus far.

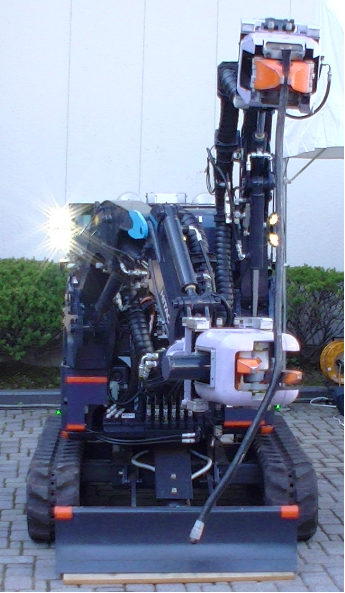

Fig.1. A small-scale double-arm machinery-type robot "ASTACO-SoRa"

The small-scale double-arm machinery-type robot “ASTACO-SoRa” makes it possible to conduct work with a high degree of freedom due to the mounting of two arms on the compact body of 980 mm in width. The arms can reach up to about 2.5m in height. One arm is capable of lifting a weight of approx. 150kg, and the both arms are capable of lifting a total weight of approx. 300kg.

In addition, the capability to exchange tools allows the robot to deal with a broad range of works.

Since ASTACO-SoRa is designed to deal with works such as rubble removal within the reactor building in NPP, wireless remote control is required.

ASTACO-SoRa has great value because of its many functions to support the operator, while being completely remote controlled.

Phase 2 : Industrial Confirmation Phase

- (1) Components: within the Reactor building / Turbine building

- (2) Location:

Floor

- (3) Material: Not Applicable

- (4) Condition: Disaster site, Radiation environment

- (1)Mounting two arms on the compact body

- ASTACO-SoRa makes it possible to travel through narrow passages due to a compact body of only 980 mm in width, but also to conduct works with a high degree of freedom due to the mounting of two arms. The arms can reach up to about 2.5m in height. One arm is capable of lifting a weight of 150kg, and the both arms are capable of lifting a total weight of 300kg. (Table 1)

ASTACO-SoRa is capable of going up steps as high as 80 mm and slopes as steep as 10 degrees. ASTACO-SoRa is drive by a diesel engine and the application of the diesel engine makes it possible to operate ASTACO-SoRa for about 15 hours wirelessly.

Table 1 Main specification of ASTACO-SoRa Name A small-scale double-arm machinery-type robot Weight approx. 2.5 ton Dimensions Crawler width:980~1280mm variable

Length:1570mm

Height:1500mm (minimum including arms)Drive system Diesel engine

Rated output 11kW/min-1(15PS/2400rpm)Fuel Diesel Fuel tank volume 19.5 liters Operating time About 15 hours (continuous use) Lift Capacities Both: Approx. 300kg

One: Approx. 150kgTravel speed 2.6 km/h Operating method Wireless remote control (emergency : wired control)

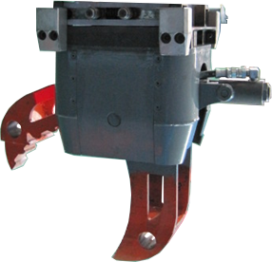

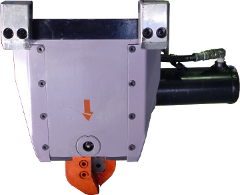

- (2)Exchangeable tools provided at the end of the arms

- The tools such as hand tool, rotor tool, shear cutting tool and circular saw tool provided at the end of the arms of ASTACO-SoRa are exchangeable to deal with a broad range of works.

These tools are remotely exchangeable and this remote exchange provides the robot with flexibility to adjust its capabilities to match the work needs based upon the on-site situation. Figure 2 shows these tools and Movie shows action of exchanging tools.

ASTACO-SoRa is equipped with two arms so that a different tool can be attached to each arm. The two arms make it possible to deal with rubble removal within the NPP reactor building and decommissioning operation carefully. For example, ASTACO-SoRa can cut the rubble with one arm while gripping the rubble with the another arm.

Handtool Rotortool Shear cutting tool Circular saw tool

Fig. 2 Tools provided at the top of arms of ASTACO-SoRa

- (3)On-site environmental measurement

- ASTACO-SoRa is equipped with cameras, a dosimeter, a thermometer, a hygrometer, a hydrogen meter, an oxygen meter and an infrared camera. The data measured by these sensors is continuously displayed at the remote control panel and can be saved to a hard disk for later analysis. This information can also be used to monitor the environment in the building around ASTACO-SoRa.

ASTACO-SoRa resists a cumulative dose of 100Gy.

- (4)Support of remote control

- The control of ASTACO-SoRa operation is remotely conducted by a remote control panel with joysticks for exclusive use. The joysticks contribute to the mitigation of burdens on operators. The remote control panel is capable of displaying 5 monitors simultaneously while switching the pictures of 6 cameras mounted on a robot. Since these six cameras are equipped with LED light, ASTACO-SoRa can deal with rubble removal within the reactor building in NPP which is dark disaster site. Figure 3 shows the remote control panel of ASTACO-SoRa.

A clinometer equipped by ASTACO-SoRa prevents ASTACO-SoRa from falling during operation. If perchance ASTACO-SoRa falls, it can return using its arms. In addition, the exclusive lifter makes it possible to salvage ASTACO-SoRa in an emergency.

Fig.3 Remote control panel of ASTACO-SoRa

Table 2 Main specification of remote control panel Weight 400kg Dimensions Width:1600mm

Length:1010mm

Height:1635mm

Movie

- Movie Contents

1. Specification

(1) Dimension

(2) Weight

(3) Lift Capacities

(4) Boom movable range

(5) Body

(6) Crawler

2. Attachments

(1) Attachment handling range

(2) Attachment

(3) Exchanging tool

(4) Action of exchanging attachments

3. Origin returning function

(1) Origin returning function mode - 1

(2) Origin returning function mode - 2

4. Measuring equipment

5. Remote operating console

ASTACO-SoRa has been successfully utilized for the rubble removal in the reactor building in Fukushima Daiichi NPP.

Fig.4 The rubble removal in the reactor building in Fukushima Daiichi NPP

- [1]E-JAM Vol.5, No.2, NT-57

(Remote Control Monitoring Robot System in Large-Scale Disaster Scenes) - [2]Hitachi-GE Nuclear Energy, Ltd. Homepage

(http://www.hitachi-hgne.co.jp/news/2012/20121207.html) - [3]TEPCO Homepage

(http://www.tepco.co.jp/nu/fukushima-np/handouts/2013/images/handouts_130724_07-j.pdf) (http://www.tepco.co.jp/nu/fukushima-np/handouts/2013/images/handouts_130726_05-j.pdf)

Japan Society of Maintenology (ejam@jsm.or.jp)